M series industrial-grade high-pressure pump uses: immersion lubrication crankshaft rotation, wear-free ceramic plunger, forged brass pump body and stainless steel valve.

It can work continuously for 24 hours without interruption.

Humidification spray, artificial landscape, high-pressure spray cooling, high-pressure cleaning, and cleaning system supporting.

1. Safety matters

1.1 In order to ensure the safe use of this pump, it is strictly prohibited for users to operate this pump without reading the instruction manual to prevent accidents and unnecessary losses.

1.2 If the machine is powered by a motor, the grounding of the machine must be safe and reliable, and a leakage protection switch or a safety protection device must be installed at the power terminal.

1.3 (CD 15W-40) oil should be added to the crankcase, and the oil level should be half of the oil mark. It is strictly forbidden to operate before adding lubricating oil.

1.4 When stopping use, the power supply of this pump should be cut off first, and then the water source should be turned off.

1.5 The pump outlet pressure should be matched reasonably, and the pump pressure should not exceed the maximum working pressure during use.

1.6 In order to prevent impurities from being sucked into the water inlet pipe, a filter with sufficient filtering area must be installed, and the mesh number of the filter is required to be no less than 40 mesh/inch.

2. Features and uses

2.1 Features

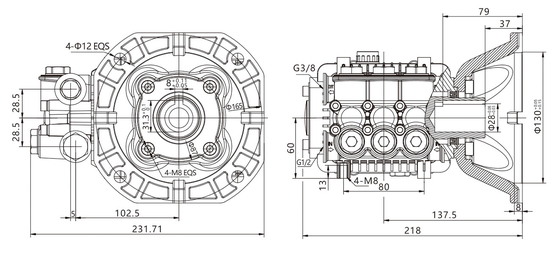

BM type three-cylinder plunger pump is a high-pressure, high-speed light and small three-cylinder plunger pump. The pump has a high speed and can be directly connected to a 4-pole motor without the need for deceleration equipment.

The pump has compact structure, small volume and light weight.

2.2 Purpose

This device is mainly used to transport clean water at room temperature.

This device is suitable for high-pressure cleaning machinery, agriculture, forestry and plant protection machinery, water-saving irrigation machinery, pressure calibration equipment, etc.

3. Working principle

The power is transferred through the crank connecting rod mechanism to convert the rotational motion of the crankshaft into the reciprocating motion of the plunger. When the plunger moves backward, due to the vacuum suction, the water inlet valve opens and the water outlet valve closes, and water is sucked into the cylinder; when the plunger moves forward, As the water pressure in the pump rises, the inlet valve is closed, the outlet valve is opened, and the high-pressure water is discharged from the outlet valve through the high-pressure pipe.

The establishment of pump pressure depends on the size of the damping of the pump outlet. Large damping means high pressure, and vice versa.

4. Pressure regulating valve

The pressure regulating valve is mainly composed of a pressure regulating cover, a pressure regulating spring, a valve stem and a ball valve seat, a check valve seat and a check valve core.

This pump is equipped with a pressure regulating valve model is 3/8 external return water pressure regulating valve

The functions of the pressure regulating valve include: ① It can regulate the pressure. ②When the spray gun is opened to spray, the pressure immediately reaches the set value, and when the spray gun is closed, the pump pressure immediately drops below 1Mpa. If the unloading valve is not installed, the pressure when the gun is turned off will be higher than that during spraying, and will consume more power than when it is working. Therefore, using an unloading valve is an effective way to save energy. Under normal circumstances, it can save about 30%.

5. Use and operation

5.1 Preparation

Before use, you should pour lubricating oil (N68-GB3142-82) into the crankcase to half the oil mark.

Connect the matching water outlet pipe, water inlet pipe, suction filter screen and bypass pipe, etc., and check whether the fasteners and the pipe joints are loose.

Connect the inlet and outlet pipes of the pump, and there should be no less than 40 mesh/inch filter device at the end of the inlet pipe to prevent debris from entering the pump and affecting the normal operation of the pump.

5.2 Start-up and operation

Generally, the unloading valve has been adjusted to the rated pressure, and no further adjustment is necessary. If you need to adjust the pressure, you should fire the gun first. After firing, turn the pressure regulating handwheel of the unloading valve while spraying to make the pressure reach the predetermined value. To start working.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!